E-posta biçimi hatası

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

resetAccountPassword

forTheAccount

pwdLetterLimtTip

inconsistentPwd

resetSuccess

resetSuccessTips

login

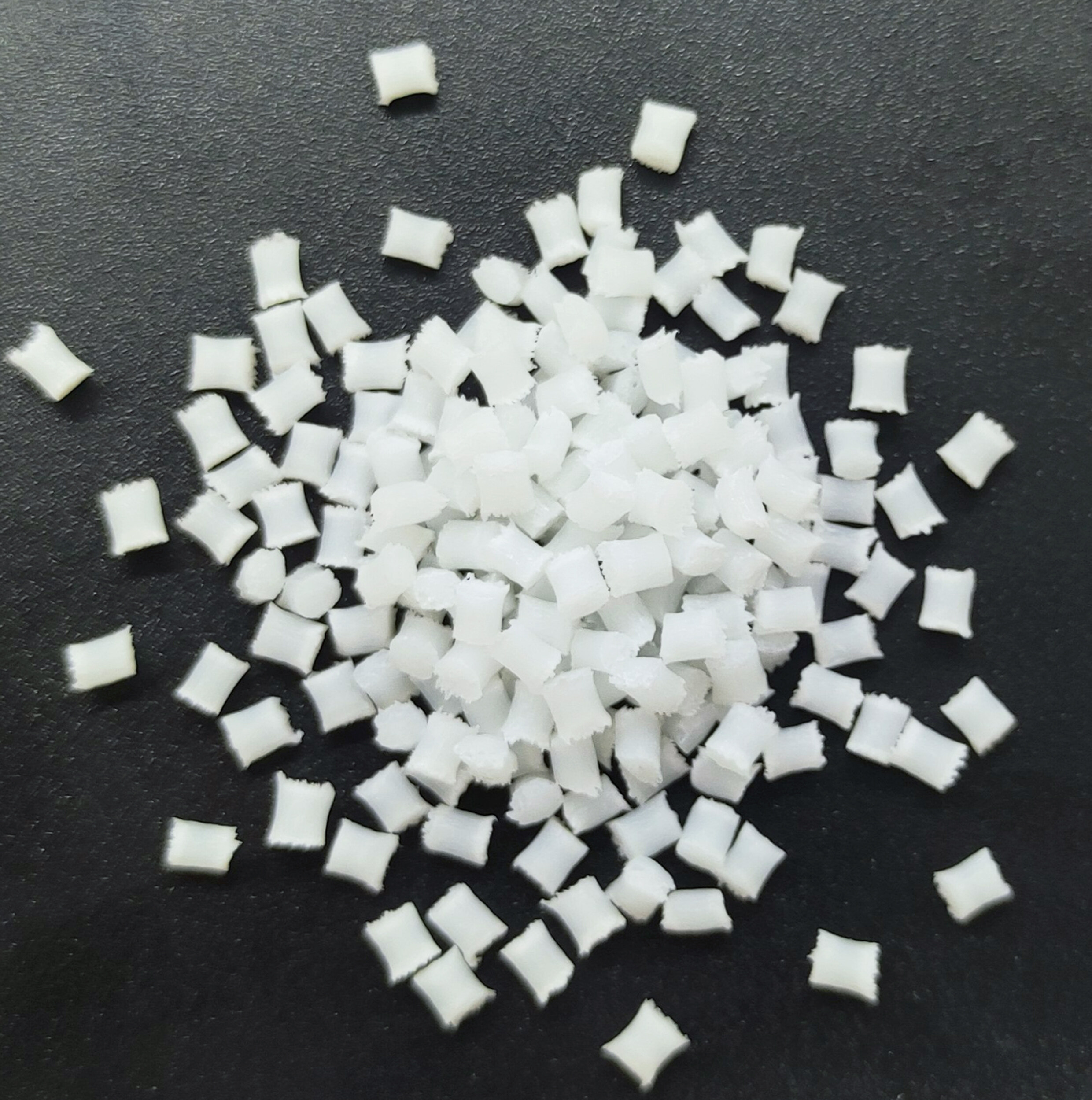

How to increase the toughness of nylon products?

2024-06-03 10:33:02

1.Why are the newly made nylon PA6 parts so brittle?

How long do they need to be stored before destructive testing? In this issue, let's talk about the process in this area. As for nylon materials, everyone knows that they must be dried before injection molding, otherwise there will be water splashing and peeling. After the material is dried, the newly made product has no water at all. At this time, it needs to be fully absorbed. Because nylon has a characteristic, that is, after the cell water is absorbed, its toughness will be the best. Just like cement bricks, when they are just made, they must be watered on the bricks. I have sorted out a few points about the water absorption process of the product, and you can save them.At present, the most common method is to soak the product directly in water after it is made. If conditions permit, it can be boiled in 100-degree boiling water. Another method is to use a steamer for products with high requirements and urgent delivery. The toughness of the product will be immediately reflected after steaming for three hours. There is also a laziest method. After the product is made, put it in a ventilated place for ten days, and the same effect will appear, but it takes up more space. These methods are the process of making the product absorb water. If the toughness of the product still does not meet the requirements after absorbing water, then the material itself does not meet the standards. In addition, when injecting, try to make the product fuller. The fuller the product is, the higher its density will be, and it will look straighter.

2.suggestion

I would like to share three suggestions with you. First, the nylon products just mentioned are relatively brittle and can be soaked or boiled. Second, toughening agents can be added to improve toughness, but this will also cause the product strength to decrease. Finally, reinforced filled products can reduce the content of fillers to reduce their strength. In this way, the toughness is relatively improved. Adding glass fiber to nylon can greatly improve the tensile strength and bending strength of the material, improve the heat resistance, dimensional stability, rigidity, and mechanical properties (tensile strength and bending strength) of nylon, especially the mechanical properties. It has become an excellent engineering plastic and is widely used in gears, bearings, fan blades, pump blades, bicycle parts, automotive industry parts, fishing gear and some precision engineering products.Nylon PA material is entrusted with important tasks in industrial production due to its excellent performance, but it is a crystalline thermoplastic. Rapid cooling during injection molding prevents the material from naturally crystallizing and setting, resulting in strong internal stress inside the material. After setting, the macromolecules will still tend to move in a natural orientation and crystallize, causing further aggravation of the internal stress of the material, and brittle fracture is likely to occur, causing trouble in production. After moisture conditioning treatment such as boiling, increasing the water vapor content in the component can effectively improve its fragility.

What is boiling and humidity conditioning treatment? It allows nylon materials to be soaked in water at a certain temperature, allowing the macromolecules inside to tend to natural orientation as much as possible, achieving a balance between internal crystallization and crystallization, thereby eliminating its internal stress.

There are many ways and means of treatment. Here we teach you a method, spray a certain amount of water on the injection-molded nylon parts in a tissue package, or put a soaked paper towel in the package where the nylon parts are stored. The moisture on the wet paper towel gradually vaporizes and migrates to the nylon parts, which not only increases the moisture absorption rate, but also allows the moisture to be more evenly adsorbed on the surface of the nylon parts. Why boil in water? Because nylon contains water group Qian'an group, it makes nylon easy to absorb water. After nylon absorbs a certain amount of water, it helps the orientation and crystallization movement of its internal macromolecules. The temperature and time of boiling nylon in water are 90 to 100 degrees for 2 to 3 hours. Can boiling in water really solve the brittleness problem of all nylon products? No, if the raw material itself has been aged, degraded or formed, the molecular weight of the material will decrease during the processing, which will cause its performance to change. In this case, boiling and humidifying will have little effect. From this, we can conclude that after the debugging treatment, the toughness of the polymer material is improved, but during the debugging process, people tend to input a large amount of moisture into the polymer in a short period of time, and the polymer cannot contain so much moisture for a long time. After a period of time, the excess moisture will escape. The polymer material returns to a brittle state, especially when the material has aged, the polymer's ability to contain moisture decreases, and the improvement of the toughness of the material by the moisture extraction treatment becomes more limited.

Bize Ulaşın